Raise Your Product Style with Extrusion of Plastics Experience

Plastic Extrusions: Versatile Applications and Advantages of Plastic Extrusions

Are you interested regarding the versatility and benefits of plastic extrusions? Look no more!

In this article, we'll discover the various applications of plastic extrusions as well as just how they can enhance producing processes. Discover how plastic extrusions can boost item layout and also functionality, along with their duty in building projects.

Furthermore, we'll explore the environmental advantages of making use of plastic extrusions.

Distort up and get ready to discover all regarding the amazing world of plastic extrusions!

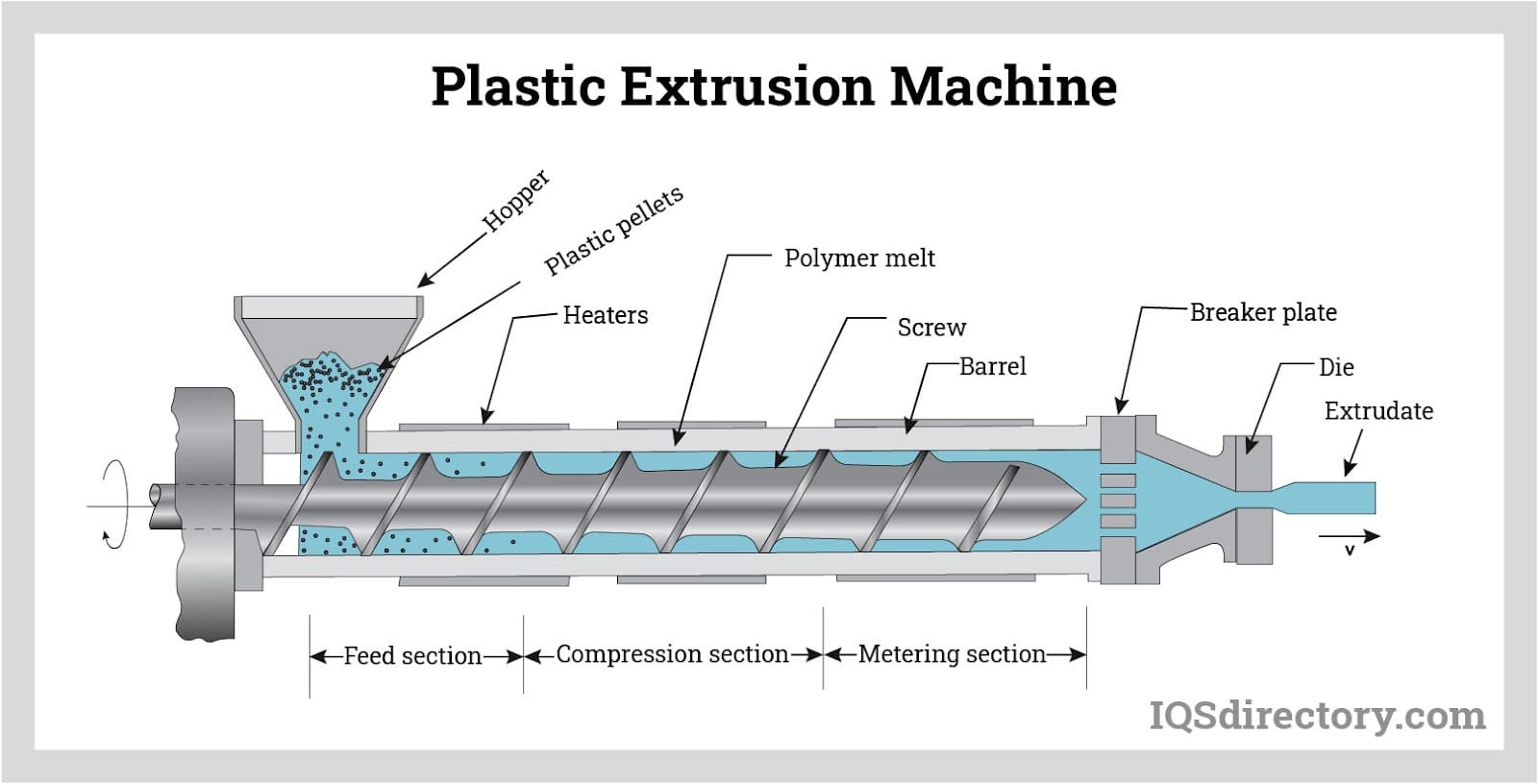

5 Common Applications of Plastic Extrusions

Plastic extrusions are commonly utilized in various sectors for their versatility and effectiveness. In your kind of work, you may find plastic extrusions in a multitude of applications.

One common application remains in the building and construction market, where plastic extrusions are utilized for home window frameworks, door seals, as well as even attractive trim. These extrusions supply an economical solution while keeping durability and climate resistance.

Plastic extrusions play a substantial role in producing different components like weatherstripping, seals, and also gaskets when it comes to the automobile sector. extrusion of plastics. The adaptability of plastic extrusions enables for easy modification to fit certain lorry layouts, lowering as well as making sure a tight seal sound and resonance

The durable goods industry additionally gains from plastic extrusions. You may discover them in items like furnishings, devices, as well as electronics. Extrusions are made use of for edge banding, protective covers, as well as even cord monitoring systems, offering both capability as well as visual charm.

Another essential industry that makes use of plastic extrusions is the clinical field. These extrusions are usually utilized for tubing, catheters, and also various other medical devices. The capability to produce intricate shapes and dimensions with precise resistances makes plastic extrusions a dependable option in health care applications.

Benefits of Plastic Extrusions in Manufacturing Processes

When it pertains to making procedures, you can take advantage of the flexibility and also cost-effectiveness of utilizing plastic extrusions.

Plastic extrusions supply many advantages that make them a prominent option in different markets. Plastic extrusions can be tailored to fulfill certain design needs, enabling you to create intricate shapes and also profiles that are hard to achieve with various other materials (extrusion of plastics).

An additional advantage is the cost-effectiveness of plastic extrusions. Compared to other making methods, such as shot molding or machining, plastic extrusions are typically more affordable. The extrusion procedure is highly effective, causing very little waste and also lower manufacturing prices. Furthermore, plastic extrusions call for less finishing and also post-processing, further decreasing expenses.

Plastic extrusions likewise supply superb toughness and resistance to various environmental variables. They are resistant to corrosion, UV radiation, as well as chemicals, making them suitable for severe settings and exterior applications. Furthermore, plastic extrusions can be engineered to possess certain homes such as fire retardancy or electric conductivity, boosting their viability for details industries or applications.

Just How Plastic Extrusions Enhance Item Layout as well as Performance

To enhance your product design as well as performance, you can make use of the modification alternatives and also cost-effectiveness supplied by plastic extrusions.

Plastic extrusions give a versatile solution for numerous markets and applications. By utilizing plastic extrusions, you can create custom accounts with intricate forms and dimensions, enabling you to develop items that completely fit your details demands. Whether you need networks, tubes, or profiles with elaborate styles, plastic extrusions can be tailored to fulfill your specific specs.

One of the crucial benefits of plastic extrusions is their ability to offer cost-effectiveness. Compared to various other producing procedures, plastic extrusions are relatively inexpensive, making them an affordable alternative for services of all sizes.

Furthermore, plastic extrusions use outstanding performance. They are light-weight, durable, and also immune to different environmental factors, such as wetness, UV radiation, and also chemicals. These buildings make plastic extrusions suitable for exterior applications, where items need to endure severe conditions. In addition, plastic extrusions can be conveniently YOURURL.com machined, drilled, or welded, providing you the flexibility to integrate extra functions and also components into your item layout.

Exploring the Versatility of Plastic Extrusions in Building And Construction

The adaptability of plastic extrusions in building is obvious in their capacity to create custom accounts with intricate forms and also measurements. When it involves building buildings or various other browse around this site frameworks, plastic extrusions provide a large range of advantages.

One of the primary advantages is their flexibility in design. With plastic extrusions, you can develop profiles that flawlessly fit your certain building needs. Whether you call for a rounded shape for building purposes or an one-of-a-kind style for functional factors, plastic extrusions can quickly suit your demands.

In addition to their capacity to create custom accounts, plastic extrusions are durable as well as also lightweight. This makes them optimal for construction tasks where weight is an issue, such as in roof or cladding applications. In addition, plastic extrusions are resistant to rust, UV rays, and also extreme climate condition, ensuring their durability and also reliability.

Another benefit of plastic extrusions in building and construction is their cost-effectiveness. Compared to various other materials, such as wood or metal, plastic extrusions are frequently a lot more affordable. They also call for very little upkeep, lowering long-lasting expenses.

On the whole, the convenience of plastic extrusions in construction enables limitless possibilities in design as well as performance. From home window frames to pipes, from ornamental trims to structural elements, plastic extrusions have actually come to be an important part of contemporary building. So, following time you're preparing a building task, consider the versatility and also benefits that plastic extrusions can offer.

The Environmental Advantages of Making Use Of Plastic Extrusions

Making use of plastic extrusions in building and construction tasks not just provides style flexibility and cost-effectiveness, yet also brings ecological benefits. By incorporating plastic extrusions into your building projects, you can add to an extra sustainable future.

Among the crucial ecological advantages of making use of plastic extrusions is the reduced waste and also power intake. Unlike typical construction materials, click here for more plastic extrusions can be manufactured to exact specifications, decreasing waste during the production procedure. extrusion of plastics. In addition, plastic extrusions are light-weight, which means that transportation calls for much less gas, lowering carbon exhausts

An additional advantage of plastic extrusions is their resilience and durability. Unlike timber or steel, plastic extrusions are immune to rotting, rusting, as well as corrosion.

Furthermore, plastic extrusions are often made from recycled materials, further minimizing their ecological effect. By choosing these eco-friendly products, you can actively join the circular economic situation as well as add to the reduction of plastic waste.

Conclusion

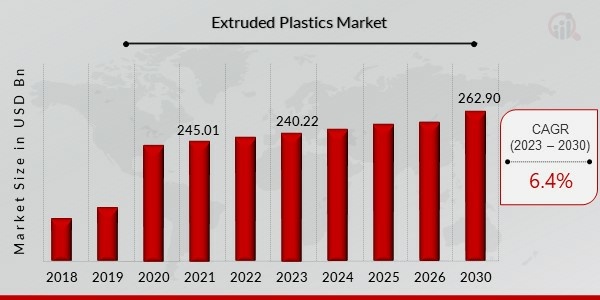

To conclude, plastic extrusions provide a wide variety of applications as well as advantages in different sectors. You can use them in making processes to enhance performance and cost-effectiveness.

They additionally enhance item layout as well as functionality, making your products attract attention out there.

Plastic extrusions are flexible in construction, providing sturdy and personalized solutions.

Moreover, utilizing plastic extrusions adds to ecological benefits, as they are recyclable and also minimize waste.

Consider incorporating plastic extrusions right into your jobs for their versatility and many benefits.

The customer goods market also profits from plastic extrusions. By utilizing plastic extrusions, you can create custom-made profiles with complicated forms and also measurements, allowing you to make items that perfectly fit your particular demands. One of the key advantages of plastic extrusions is their capability to provide cost-effectiveness. Plastic extrusions can be conveniently machined, drilled, or welded, giving you the versatility to integrate additional functions as well as elements right into your product style.

One of the essential environmental advantages of making use of plastic extrusions is the lowered waste and also energy usage.